Excavation machines are crucial machines in the construction and excavation industries, recognized for their powerful capabilities and adaptability. Regardless of whether for large-scale projects or smaller tasks, comprehending the basic parts of an excavator can substantially increase the performance and functionality of these machines. As we dive into the essential components of an excavator, we will analyze how each part adds to to its overall functionality and performance.

At the heart of every excavator lies a blend of different parts that work together seamlessly. From the heavy-duty undercarriage that provides mobility to the complex hydraulic systems that enable accurate movements, each component plays a significant role. In this article, we will investigate at these fundamental parts, unpacking the inner workings of excavators and emphasizing their value in the realm of civil engineering and digging.

Main Components of Excavators

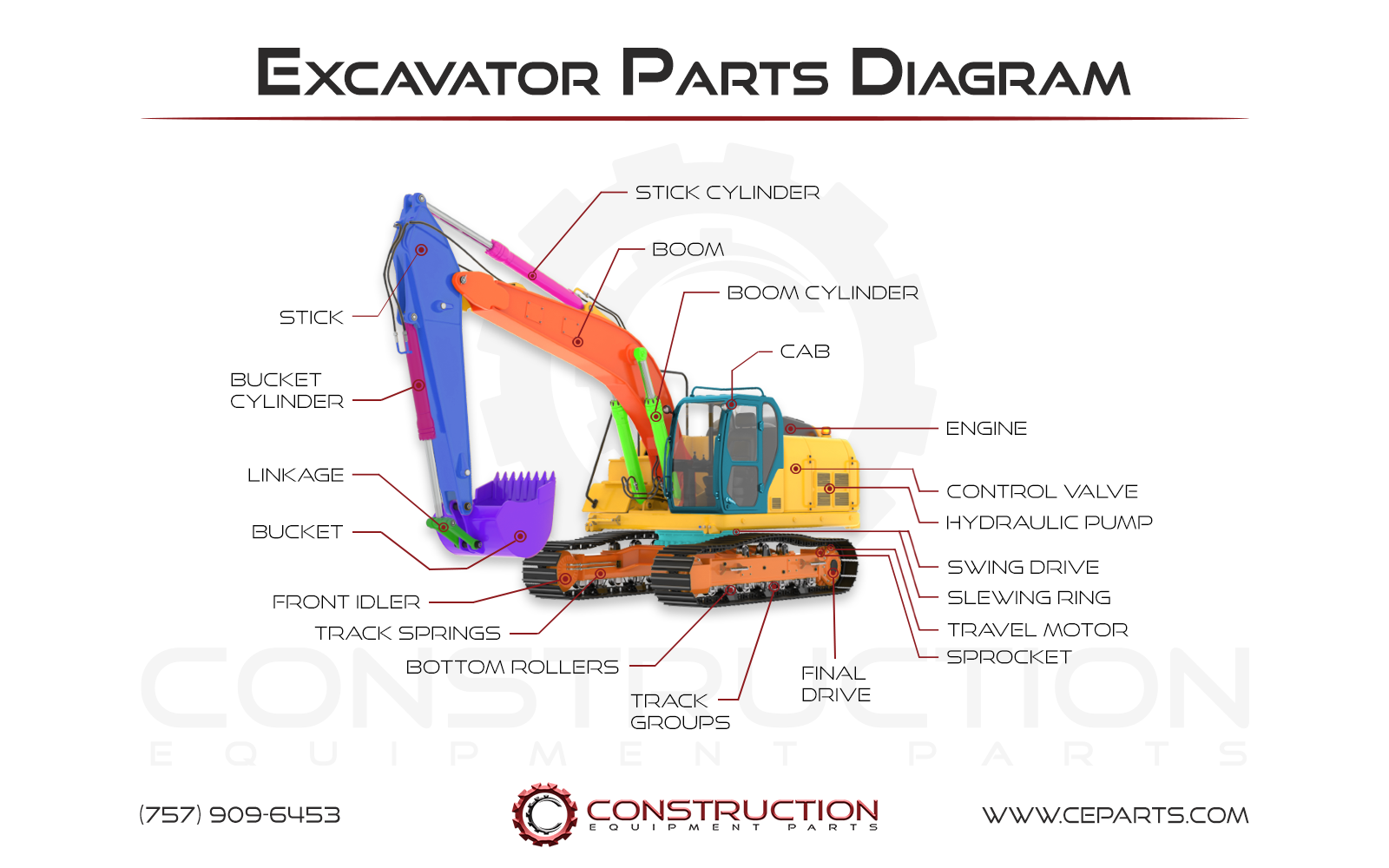

Excavator machines are complex machines designed to perform a variety of heavy-duty tasks, and comprehending their main elements is crucial. The key components that contribute an excavator's capability include the boom, stick, and scooping device. The long arm is the long arm that extends from the chassis, providing extension and height for excavating and lifting. The stick, or extension, connects to the end of the long arm and furthermore extends the excavator's capacity. Finally, the bucket, often varying in dimensions and form, is used to scoop up materials such as dirt, gravel, or waste.

A further crucial component is the base structure, which supports the complete structure of the excavator. It is made up of the tracks or wheels, depending on the type of excavator. The base provides stability and movement, allowing the excavator to maneuver across different terrains. Tracked excavators are notably effective in soft or rough surfaces, while wheeled excavators are adapted for city environments and tarred roads. The configuration of the undercarriage plays a crucial role in the excavator's capability and operational effectiveness.

Furthermore, the operator's compartment of the excavator contains the controls and provides view for using the machine safely. Inside the operator's compartment, operators can find controls and handles that control the movement of the boom, dipper arm, and bucket. The cab is often equipped with a range of features to enhance comfort and safety, such as climate control, ergonomic chairs, and safety glass. Comprehending the layout and operation of these components can significantly boost the efficiency of digging projects.

Excavator Hydraulics Mechanisms

The hydraulic system is a critical component of every excavator, providing the power needed to operate various parts of the machine. This system utilizes hydraulic fluid, which is forced through tubes and chambers to create movement. When the operator manipulates the controls, hydraulic fluid is directed to the specific cylinders, enabling the boom, arm, and bucket to operate effectively. This innovation allows for exact control and heavy lifting power, making excavators suitable for a wide range of construction tasks.

Key components of the hydraulic system consist of the hydraulic pump, hydraulic cylinders, and valves. The pump generates the necessary pressure to circulate the hydraulic fluid throughout the system. Hydraulic cylinders transform the hydraulic energy into mechanical force, allowing for linear movement of the boom and arm. Additionally, valves are crucial for controlling the flow of hydraulic fluid, ensuring that the operator can manage the action efficiently and safely.

Care of the hydraulic system is critical for the overall performance and longevity of the excavator. Regular checks for leaks, ensuring fluid levels are sufficient, and replacing damaged hoses or seals can prevent major failures and keep the system operates at peak efficiency. By keeping the hydraulic system in optimal condition, operators can rely on their excavators to perform heavy-duty tasks without interruptions.

Excavator Attachments & Accessories

These machines are flexible machines that can be equipped with a wide array of tools to boost their performance. Standard attachments include bucket attachments, which differ in dimension and form depending on the particular type of task. Digging buckets are designed for excavating soil while hard material buckets are built to cope with tougher items. Additionally, there are specialist buckets for tasks such as leveling, trenching, and demolition, allowing operators to tailor their machines based on project needs.

Beyond buckets, excavators can make use of hydraulic attachments such as impact hammers and shears. cat parts are suitable for shattering concrete and rock, while shears are helpful for cutting through steel and other hard materials. These attachments significantly boost the excavator's output and enable it to perform tasks that would otherwise require several machines. The use of hydraulic attachments allows for smooth operation, especially in building and demolition projects.

Other accessories like quick couplers and tilt rotators make easier easier attachment changes, enabling operators to swap tools quickly and smoothly. Fast couplers help in seamlessly attaching and detaching different attachments without the need for manual disassembly, saving time on the job site. Rotating tilt attachments provide extra flexibility, allowing the attachment to tilt and rotate, which enhances precision and control during operation. These tools and accessories play a key role in maximizing the efficiency and flexibility of excavators in various applications.